Chafing gear may not be the flashiest piece of equipment on a boat, but it’s one of the most important. It serves as the quiet guardian between the elements, the boat, and the lines that secure it. Whether protecting dock lines from rubbing against rough surfaces or shielding hoses from vibration, chafing gear can mean the difference between a safe vessel and one drifting away during a storm.

Chafing itself is the gradual wearing away of material caused by friction. On boats, it most often affects dock lines, mooring lines, and hoses that experience constant movement or vibration. When a line shifts slightly back and forth under tension — such as a dock line rubbing on a cleat, piling, or fairlead — it begins to abrade. Over time, those tiny fibers fray, weakening the line until it finally gives way. The same principle applies to rubber hoses in engine compartments, which can rub or vibrate against other parts and eventually split. A small area of wear can turn into a major failure if left unprotected.

That’s where chafing gear comes in. Its purpose is to act as a sacrificial layer between a vulnerable line or hose and the hard surface it touches. Instead of the line or rubber wearing down, the protective sleeve absorbs the abuse. When properly installed, it prevents breakage, extends the life of expensive marine-grade lines, and offers peace of mind during rough conditions.

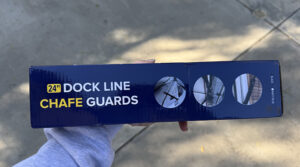

Commercially available chafing gear comes in a variety of forms. Companies such as Taylor Made produce perimeter chafe guards made of UV-resistant polyester that easily slide through chocks and do not rot or split under sun exposure. These guards are designed to withstand the harsh combination of sun, salt, and motion, offering superior abrasion resistance for dock and mooring lines. They’re typically sold in pairs and secured with simple ties. Many marine stores also sell Velcro-style sleeves, canvas wraps, and heavy-duty webbing guards that can be installed or removed without untying a line.

For boaters who prefer a traditional look or more permanent solution, leather chafe guards remain a popular option. Leather’s natural durability and flexibility make it ideal for long-term use, especially on larger vessels where lines are constantly under heavy load. Nylon or canvas sleeves are another choice for lightweight protection and are easy to slide over a line before docking or anchoring.

However, many boaters prefer to make their own chafing gear, especially for custom fits or budget-friendly solutions. The do-it-yourself approach is straightforward and can be surprisingly effective. One of the oldest and most reliable methods involves using sections of old fire hose. Many fire departments periodically replace their hoses and will often give away the old ones. The material is durable, breathable, and designed to handle friction, making it ideal for marine use.

To make your own chafing gear, start by cutting a section of fire hose about twelve to eighteen inches long, though longer pieces can be used for larger applications. Open the hose so that it forms a sleeve, then use an awl, ice pick, or knife to make a small hole roughly an inch from one end. Thread a short piece of thin line through that hole and use it to tie the sleeve to the boat or dock — not to the main dock line itself. This is important because the larger line will stretch and move as the boat shifts, while the chafe guard needs to remain stationary. When secured properly, the main line slides smoothly through the sleeve, protected from rough edges and constant rubbing.

Some boaters substitute old garden hose for fire hose, but this material can trap heat and moisture. When friction occurs, the buildup of heat can damage the fibers of synthetic lines, leading to premature wear. Fire hose or canvas is preferable because it allows air and water to pass through, keeping the linecooler and more flexible.

If you are using rubber or reinforced hose to protect smaller hoses in an engine compartment, the process is similar. Choose a larger diameter hose and cut it to length so it can slip over the smaller one that needs protection. This method is useful for areas where vibration from the engine causes hoses to rub against brackets, bulkheads, or other surfaces. The outer sleeve absorbs the movement, saving the smaller hose from eventual cracking or leaking.

When choosing the width of a hose for chafe protection, select one that’s just large enough to fit around the line or hose without compressing it. A snug but moveable fit is ideal, allowing the line to slide smoothly within the sleeve. For example, a five-eighths-inch dock line might pair well with a three-quarter-inch or one-inch hose section. Oversized hose will slip out of place, while one that’s too tight will restrict the line’s flexibility.

The lifespan of dock lines depends heavily on how well they’re cared for and protected. Even the best marine-grade linewill eventually weaken under the combined effects of UV exposure, saltwater, and friction. Ropes that are left to rub against hardware or exposed to direct sunlight degrade faster, losing strength and elasticity. Over time, this wear can become dangerous, especially during storms or strong tides.

There are several signs that a dock line is nearing the end of its life. Fraying or fuzziness along the surface indicates that the outer sheath is breaking down. Stiffness or discoloration often signals UV damage, while soft or flattened spots may suggest internal weakening. Cuts or nicks are also warning signs that a line should be replaced immediately. Even with light use, most synthetic ropes begin to lose strength after several years, and many manufacturers recommend replacing dock lines at least every five to seven years depending on exposure.

To extend the life of your lines, rinse them with fresh water regularly, especially after saltwater exposure, and store them out of direct sunlight when not in use. Avoid leaving them under constant tension and check them often for early signs of wear. Chafing gear should also be inspected periodically and replaced if it shows cracking, hardening, or splitting.

A good rule of thumb is to treat your dock lines as you would any other critical safety gear on your boat. They deserve regular inspection and maintenance, and chafing gear is an inexpensive way to ensure they perform reliably. Even a short burst of wind or a single passing wake can cause enough motion to wear through an unprotected line.

Whether you choose a commercial product or a do-it-yourself solution, the key is prevention. Installing chafing gear before visible wear begins ensures your lines and hoses stay intact when you need them most. For a small investment of time and materials, boaters can safeguard their equipment, extend the lifespan of their dock lines, and protect their vessels from costly damage.

Chafing gear works quietly and without recognition, but its role on board is vital. From the dock to the engine room, it stands as a simple yet effective defense against friction, heat, and time. For boaters who value reliability and safety, this small piece of equipment earns its place among the essentials—proof that sometimes, the smallest details make the biggest difference.